Sehlahisoa

Mosebetsi o felletseng oa granulation le katleho e phahameng ea tlhahiso

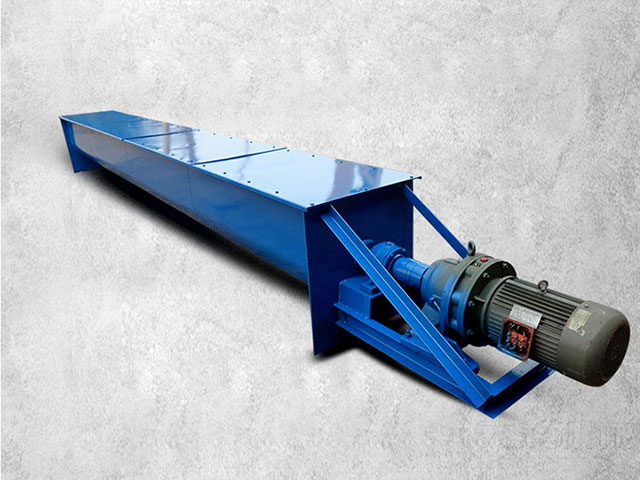

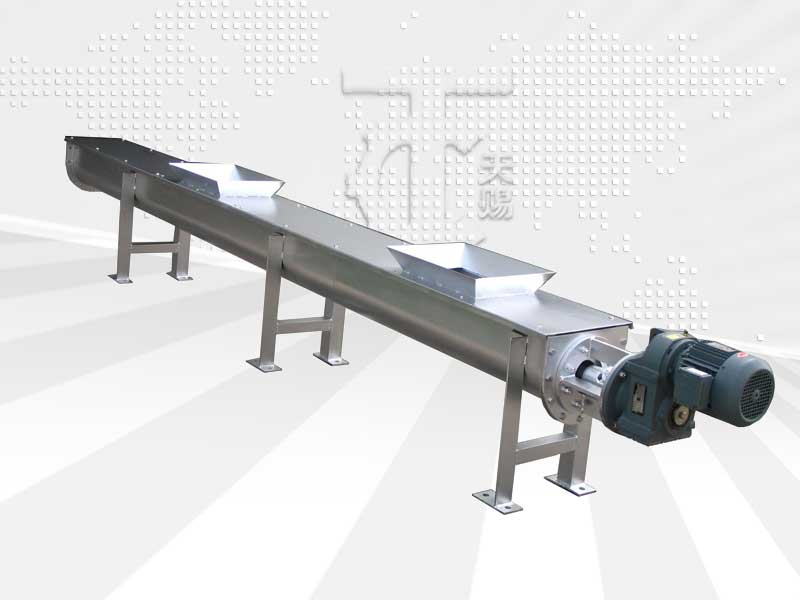

Screw conveyor bakeng sa manyolo / lik'hemik'hale / indasteri le metallurgy

Tlhaloso ea Sehlahisoa

The screw conveyor e nka cylinder ea tšepe e fetisang cylinder, e nang le boits'oaro bo phahameng, ts'ebetso e ntle ea ho tiisa, ha e lutle, 'me e ntlafatsa tikoloho ea ts'ebetso.

Sesebelisoa sa phetisetso se nka mochini o fokotsang motlakase o hokahaneng ka kotloloho oa cycloidal pinwheel, o nang le matla a phahameng, lerata le tlase, sebopeho se kopaneng le phetiso e tšepahalang.Mochine oohle o ka kenngoa ka holimo kapa oblique, o nang le maoto a manyenyane, ho kenya habonolo le ho sebelisoa habonolo.

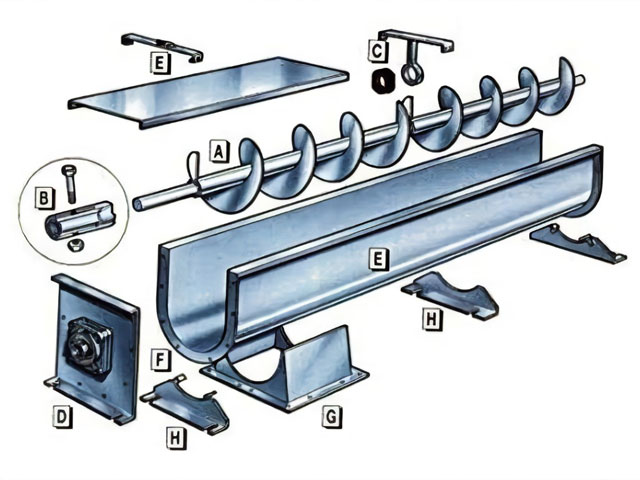

Mochine o ka aroloa ka likarolo tse tharo

1. The screw conveyor ke mofuta o sa tsitsitseng o seng oa motheo.E entsoe ka mochine oa motlakase oa geared le tube ea casing, 'me kopano ea screw e hokahane ka lehlakoreng le leng,' me e kopantsoe ho ba sete e feletseng ea thepa, e leng bonolo haholo ho sisinyeha, ho qhaqha le ho kopanya.

2. Kopano ea screw le qetellong ea shaft li kopantsoe ke li-splines, tse bonolo ho li bokella le ho li qhaqha, li na le matla a maholo a ho jara, ho se jele paate, 'me ho bolokehile ebile ho ka tšeptjoa.

3. Ts'ebetso ea ho tiisa e ntle, khetla e entsoe ka phala ea tšepe e se nang seamless, 'me qetellong e' ngoe le e 'ngoe e kopantsoe ke li-flanges, mochine oohle ha o na lerōle le leleak,' me ha ho na lisebelisoa tse senyang, e le ho theha sebaka se setle sa ho sebetsa le ho kopana le tšireletso ea tikoloho. ditlhoko.

4. Boholo bo bonyenyane, lebelo le phahameng, molumo o feto-fetohang, ho netefatsa hore o potlakile esita le ho pepa.

5. Sebaka sa ho fepa se ka etsoa ka lehlakoreng le hlokahalang la ho sekamela ho ea ka maemo a sebaka sa ho sebetsa, 'me se ka kopanngoa ke flange, mokotlana oa mokotla le flange ea bokahohle, e ka khethoang ke basebelisi ho ea ka litlhoko tsa bona.

Tekheniki Parameters

| Mohlala | Bophara ba spiral (mm) | Lebelo la ho potoloha (r/min) | Ho romelloa ha molumo o tloaelehileng (m3/h) |

| LS160 | 160 | 112 | 9.7-3.2 |

| 90 | 7.8-2.6 | ||

| 71 | 6.2-2.1 | ||

| 56** | 4.9-1.6 | ||

| LS200 | 200 | 100 | 16.9-5.6 |

| 80 | 13.5-4.5 | ||

| 63 | 10.7-3.6 | ||

| 50** | 8.5-2.8 | ||

| LS250 | 250 | 90 | 29.9-9.9 |

| 71 | 23.5-7.8 | ||

| 56** | 18.5-6.2 | ||

| 45** | 14.9-5.0 | ||

| LS315 | 315 | 80 | 52.9-17.6 |

| 63 | 41.6-13,9 | ||

| 50** | 33.1-11.0 | ||

| 40** | 26.4-8.8 | ||

| LS400 | 400 | 71 | 85.3-28.2 |

| 56 | 67.3-22.4 | ||

| 45** | 54.1-18 | ||

| 36** | 43.2-14.4 |

Kopa Khopolo

Khetha mohlala 'me u behe liodara

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana theko ea motheo

Baetsi ba nka bohato ba ho ikopanya le ho tsebisa lo

Tlhahlobo ea limela

Tataiso ea koetliso ea litsebi, leeto la ho boela la kamehla

Saena konteraka

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana bonyane tlhahiso ntle le tefo , ka kopo tlatsa lintlha tse latelang ho re bolella ( boitsebiso ba lekunutu , bo sa buletsoeng sechaba )

Taba ea morero

Ithute haholoanyane Kopana le Rona

Lihlahisoa tse tloaelehileng tsa carbide tse entsoeng ka samente li na le thepa e kholo, lihlahisoa tse ikhethileng li ka hlahisoa bocha 'me hlobo e felile.

Fumana khotheishene

Fumana khotheishene +8613203835178

+8613203835178