Sehlahisoa

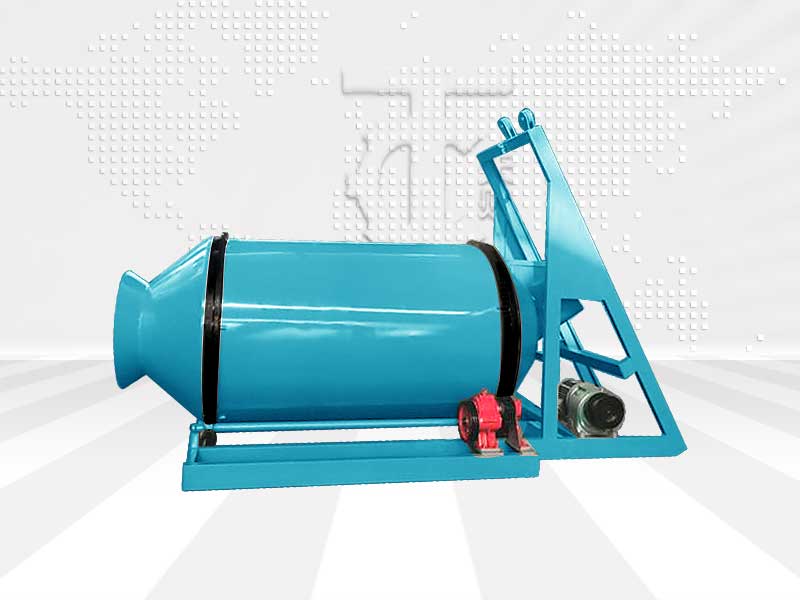

Mosebetsi o felletseng oa granulation le katleho e phahameng ea tlhahiso

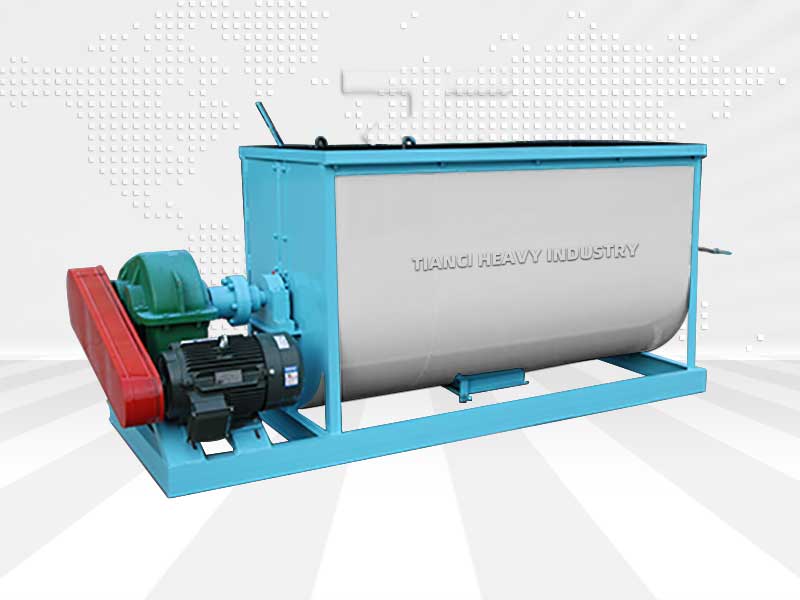

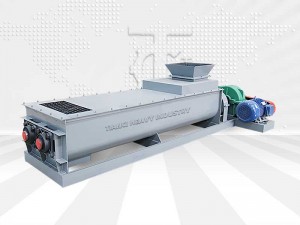

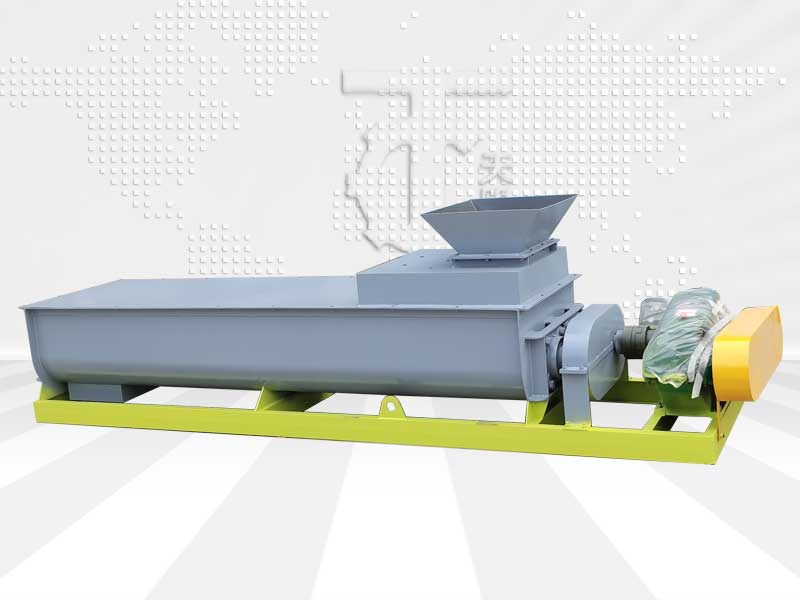

Double Shafts Horizontal Mixer

Lisebelisoa le Likarolo

1.Kakaretso ea sehlahisoa

Mochini ke setsi sa lipatlisiso tsa mochini oa temo se sebelisa lilemo tse kopaneng tsa lisebelisoa tsa ho lokisa manyolo, boiphihlelo ba tlhahiso e ntlafalitsoeng ka lihlahisoa tsa morao-rao tsa theknoloji, o fumane patent e sebetsang ea naha.E sebelisoa bakeng sa granulation ho mefuta eohle ea lintho tse phelang ka mor'a ho belisoa, ho phunyeletsa ka mokhoa o tloaelehileng oa prilling pele granulation e sa hloke ho omisa le ho pshatla lisebelisoa tse tala.E ka lebisa moroalo ho sebetsa lijo-thollo tsa cylindrical, e ka boloka matla a mangata

2.Litšobotsi tsa lisebelisoa

(1) Sehlahisoa sa granule ke cylindrical

(2) Lintho tsa manyolo li ka ba holimo ho 100%, etsa granulate e hloekileng ea tlhaho

(3) Ho sebelisa likaroloana tsa lintho tse phelang tse nang le mosaic tse tšoanang tse holang ka tlas'a matla a itseng, ha ho hlokahale hore u kenye setlamo ha se granulating.

(4) Granule ea sehlahisoa e ngata, e ka sefa ka kotloloho ka mor'a granulation ho fokotsa tšebeliso ea matla ea ho omisa.

(5) Kamora hore lintho tse belisoang ha li hloke ho omella, mongobo oa thepa e tala o ka ba 20% -40%

(6) Pele, Ho kopanya blade welding hard steel tool bit, ts'ebetso e hananang le eona e ntle, bophelo bo bolelele ba ts'ebeletso.

Molao-motheo oa ho Sebetsa

Ntlha ea pele, tekanyo ea phofo e tala e phallela ka tanka e kopanyang ka ho bula phepelo ebe metsi a kopantsoeng tlas'a mocheso o itseng.

Ea bobeli, ho sebelisa bolelele bo itseng Shaft ka har'a vane ea ho kopanya ho kopanya phofo e tala ebe e theha leqhubu la nyutlelie le nang le mongobo o itseng.

Ntlha ea boraro, kenya leqhubu la nyutlelie ka har'a bolo 'me u hlohlelletse.Karohano eohle e susumetsang e arotsoe sebakeng sa atomization, sebaka sa Stir, sebaka sa ho tsoa.

Mekhahlelo ea mantlha ea tekheniki

| Mohlala oa ZYQ-QZ | JZQ e fokotsang lebelo | Motlakase oa motlakase | Lebelo la spindle (Y/mm) | Bophara ba ho potoloha (mm) | Bokhoni ba Prod | Boima ba KG |

| 400 | 400-1V-2 | Y160M-4-11 | 52 | 400 | 20 | 2350 |

| 450 | 500-1V-2 | Y160L-4-15 | 52 | 450 | 25 | 2620 |

| 500 | 500-1V-2 | Y180M-4-18.5 | 53 | 500 | 30 | 2980 |

| 550 | 650-1V-2 | Y180L-4-22 | 53 | 550 | 35 | 3450 |

| 600 | 650-1V-2 | Y200L1-4-30 | 52 | 600 | 40 | 3850 |

| 650 | 750-1V-2 | Y225S-4-37 | 52 | 650 | 45 | 4260 |

Kopa Khopolo

Khetha mohlala 'me u behe liodara

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana theko ea motheo

Baetsi ba nka bohato ba ho ikopanya le ho tsebisa lo

Tlhahlobo ea limela

Tataiso ea koetliso ea litsebi, leeto la ho boela la kamehla

Saena konteraka

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana bonyane tlhahiso ntle le tefo , ka kopo tlatsa lintlha tse latelang ho re bolella ( boitsebiso ba lekunutu , bo sa buletsoeng sechaba )

Taba ea morero

Ithute haholoanyane Kopana le Rona

Lihlahisoa tse tloaelehileng tsa carbide tse entsoeng ka samente li na le thepa e kholo, lihlahisoa tse ikhethileng li ka hlahisoa bocha 'me hlobo e felile.

Fumana khotheishene

Fumana khotheishene +8613203835178

+8613203835178