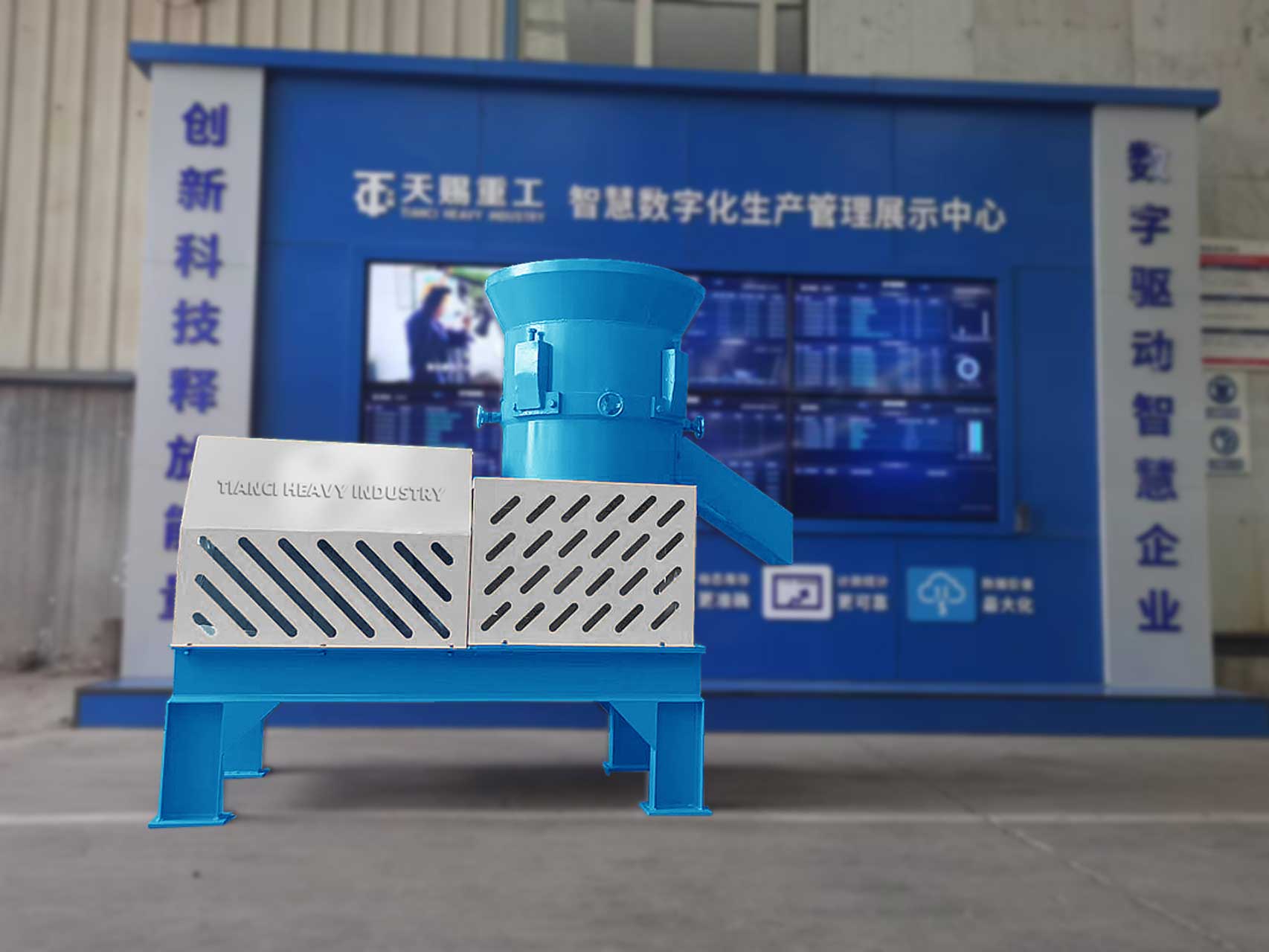

Sehlahisoa

Mosebetsi o felletseng oa granulation le katleho e phahameng ea tlhahiso

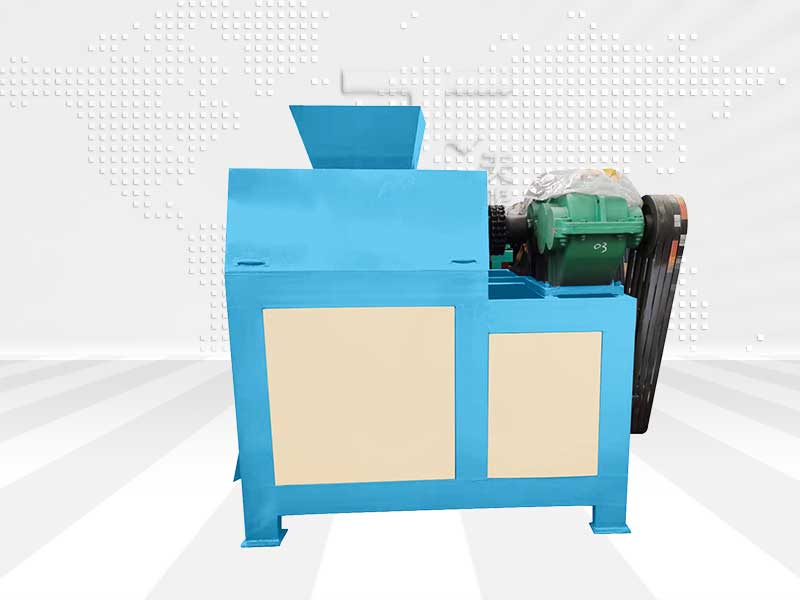

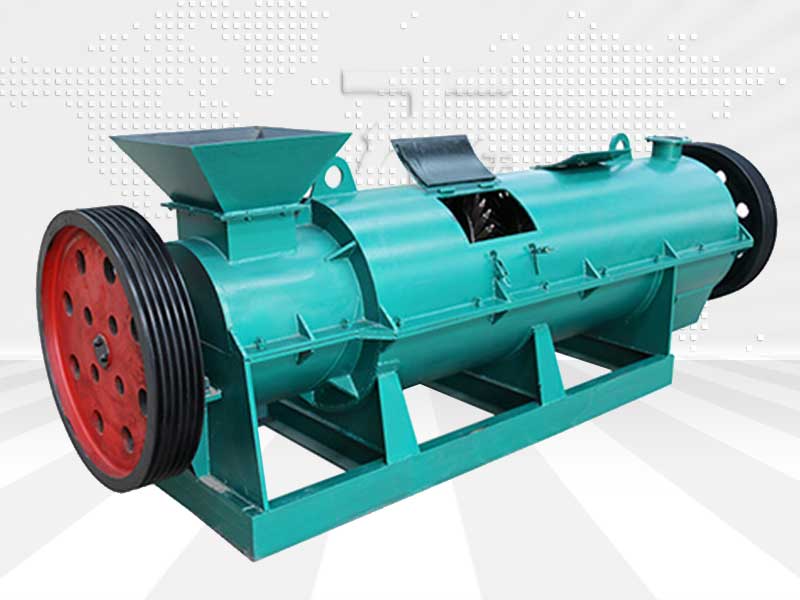

Sekhahla sa hlobo e bataletseng - hlobo ea cylindrical granulator

Lisebelisoa le Likarolo

Tlhahiso e tsoang mochine ona ke likaroloana tse chitja.

Lintho tsa tlhaho li ka ba holimo ho 100%, ho fihlela granulation e hloekileng ea tlhaho.

The granulation ha e hloke eketsa binder, tshebediso ya likaroloana manyolo ka hōlisa mong le e mong likarolo tse ling tse matla a itseng.

Granule e tsitsitse, e ka hlahlojoa ka mor'a granulation, e fokotsa tšebeliso ea matla a ho omisa.

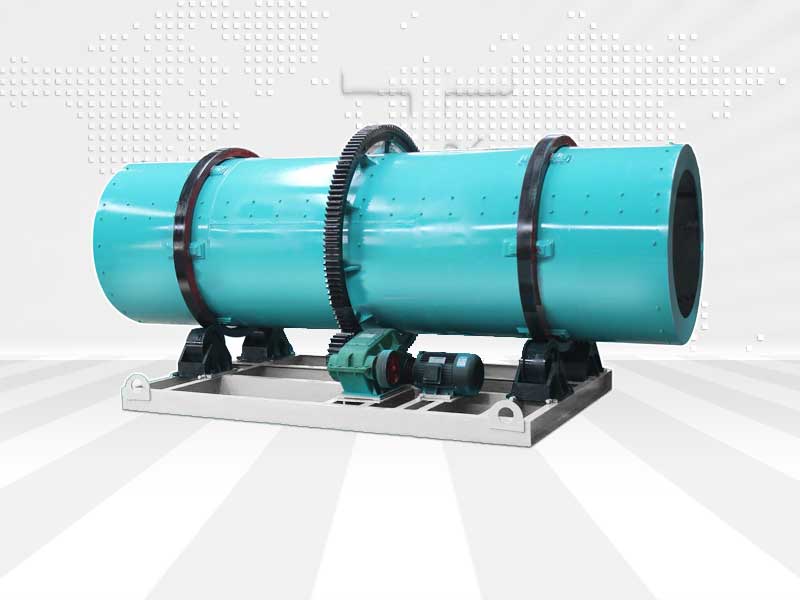

Lisebelisoa tse tala li ka ba le mongobo oa 20-40%.Thepa e tala ha e hloke ho omisoa ka mor'a ho belisoa.

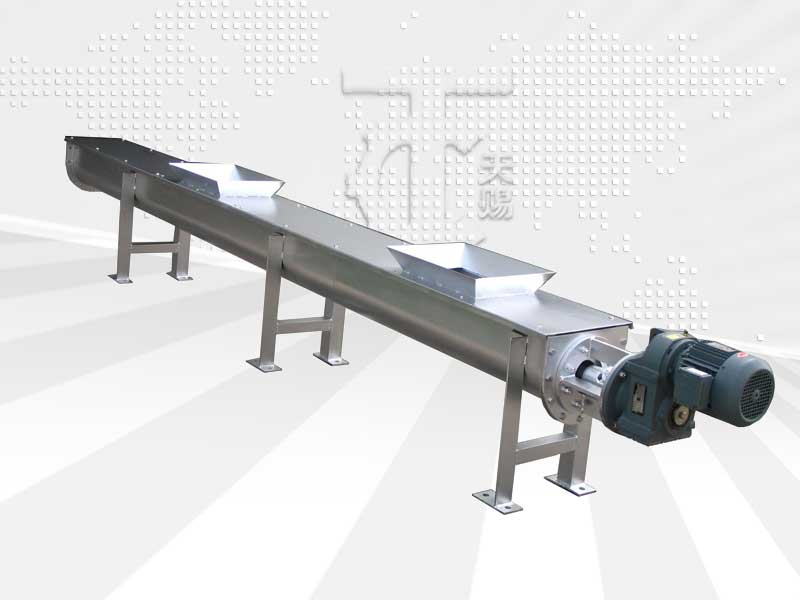

Mochini oa granulation oa manyolo o sebetsang ka bongata ke mochini oa morao-rao oa theknoloji oa granulator.E entsoe ke Setsi sa Lipatlisiso sa Mechini ea Temo se nang le boiphihlelo ba lilemo tse ngata ho lisebelisoa tsa ho lokisa manyolo.E hapile lipatente tsa mofuta oa ts'ebeliso ea mmuso.E sebelisoa bakeng sa granulation ea lintho tse fapa-fapaneng tsa manyolo ka mor'a ho belisoa, ho pshatla mokhoa o tloaelehileng oa granulation ea manyolo, ntle le ho omisa, ho sila le ho granulating lihlahisoa tse tala pele ho pelletizing, le ho sebetsana le li-granules tse chitja ka metsoako e tobileng, kahoo ho boloka matla a mangata.

Mekhahlelo ea mantlha ea tekheniki

| Mohlala | KP-400 | KP-600 | KP-800 |

| Sephetho | 1.8-2,5 | 2.5-3.5 | 4-5 |

| Sekhahla sa granulation | >95 | >95 | >95 |

| Mocheso oa karoloana | <30 | <30 | <30 |

| Karolo e bophara ba likaroloana | 3-30 | 3-30 | 3-30 |

| Matla | 30 | 55 | 75 |

| Boima ba mochini | 1200 | 1800 | 2500 |

Kopa Khopolo

Khetha mohlala 'me u behe liodara

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana theko ea motheo

Baetsi ba nka bohato ba ho ikopanya le ho tsebisa lo

Tlhahlobo ea limela

Tataiso ea koetliso ea litsebi, leeto la ho boela la kamehla

Saena konteraka

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana bonyane tlhahiso ntle le tefo , ka kopo tlatsa lintlha tse latelang ho re bolella ( boitsebiso ba lekunutu , bo sa buletsoeng sechaba )

Taba ea morero

Ithute haholoanyane Kopana le Rona

Lihlahisoa tse tloaelehileng tsa carbide tse entsoeng ka samente li na le thepa e kholo, lihlahisoa tse ikhethileng li ka hlahisoa bocha 'me hlobo e felile.

Fumana khotheishene

Fumana khotheishene +8613203835178

+8613203835178