Sehlahisoa

Mosebetsi o felletseng oa granulation le katleho e phahameng ea tlhahiso

Angle Belt Conveyor e kholo

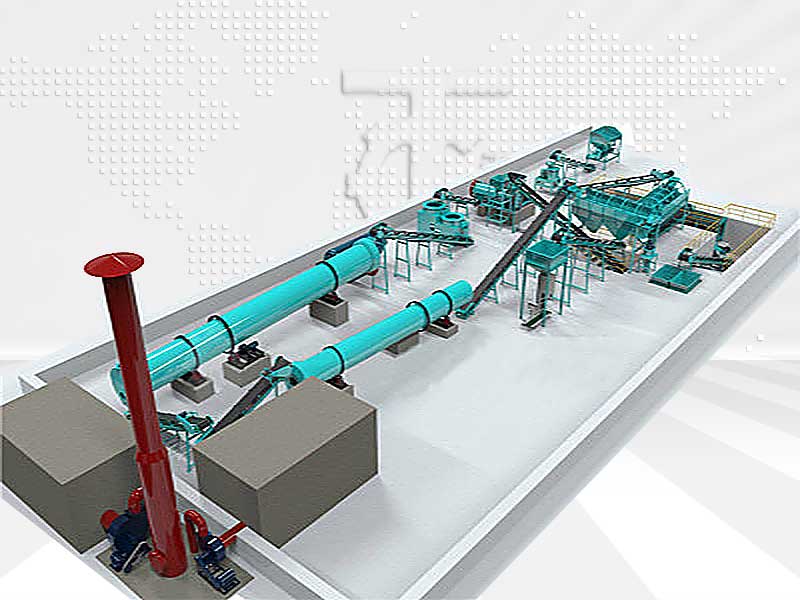

Tlhaloso ea Sehlahisoa

Ts'ebetsong ea tlhahiso ea manyolo, ka lebaka la lisebelisoa tse kholo le tšekamelo e kholo ea mekhoa e meng ea ho tsamaisa, ho tla khethoa lebanta le leholo le nang le tšekamelo.

Letoto lena la lihlahisoa tse sebelisoang haholo bakeng sa lipalangoang tse tsoelang pele tsa lisebelisoa tse ngata tse nang le angle e kholo ea ho qoelisoa, ho sebelisoa maqhubu a maqhubu le ho tšela lebanta la conveyor, angle e fetisang bakeng sa likhato tse 0-90 (likhato tse 70 ka tlase ho fetisisa) letoto la lihlahisoa li sebelisoa haholo. ka mashala, lijo, moaho, thepa, indasteri ea lik'hemik'hale, phepelo ea metsi, temo, boema-kepe, tšepe, joalo-joalo. Mefuta e fapaneng ea lisebelisoa tse ngata tse nang le sekotisty ea 0.5-2.5t/m³ mocheso o teng oa -19℃--+40℃. Bakeng sa lisebelisoa tse nang le litlhoko tse khethehileng, tse kang mocheso o phahameng kapa acid le alkali, thepa ea oli, e ka sebelisoa ho latela litlhoko tsa moralo o khethehileng oa thepa e lumellanang.

Likaroloana

Litšobotsi tsa li-conveyor tse kholo tsa lebanta ke tse latelang

(1) Thepa e kholo. Mekhahlelo ea eona ea mantlha ea tekheniki le lisebelisoa li ntse li tsoela pele ho ea ho tse kholo ho fihlela litlhoko tsa lihlahisoa tse phahameng, tse sebetsang hantle le tse matla ka tlhahiso ea selemo le selemo ea lithane tse fetang limilione tse 3-5.

(2) Tšebeliso e tlaase ea matla le katleho e phahameng. Ka lebaka la boima bo bobebe ba likarolo tse tsamaeang le molumo o monyenyane oa lipalangoang o sa sebetseng, lebanta la conveyor le na le tšebeliso e tlaase ea matla le bokhoni bo phahameng ka ho fetisisa lipalangoang tsohle tse tsoelang pele le tse sa tsoelang pele.

(3) Tšebeliso ea mechine e mengata ea mochine, koloi e bohareng le tekanyo ea matla, le mekhoa ea ho fetola tsela ea tsamaiso ea motlakase e entse hore bolelele ba ts'ebetso ea mochine o le mong bo se ke ba lekanyetsoa ka khopolo, 'me bo netefalitse ho feto-fetoha ha maemo, ho fapanyetsana ha thepa ea tsamaiso ea conveyor le ho tšepahala ha unit drive.

(4) Theknoloji e ncha le e phahameng e ka tšeptjoang ea karolo ea bohlokoa. Lisebelisoa tse fapaneng tse tsoetseng pele tsa matla a holimo le lisebelisoa tse laolang lebelo, li-idlers tse lebelo le phahameng tse nang le nako e telele ea ts'ebeletso, lisebelisoa tsa ho itlhoekisa, lisebelisoa tse bolokang mabanta tse sebetsang hantle haholo, mohatla o itsamaelang ka potlako, jj.

Tekheniki Parameters

| Bophara ba sehlopha B | 300 | 400 | 500 | 650 | 800 | 800 | |||||||||

| Block Edge e phahameng H | 40 | 60 | 80 | 80 | 120 | 80 | 120 | 160 | 120 | 160 | 200 | 160 | 200 | 240 | |

| Letoto la bophara ba hlooho | Φ200-φ316 | Φ315-φ400 | Φ315-φ500 | Φ315-φ500 | Φ400-φ630 | Φ400-φ630 | |||||||||

| Bophahamo ba lipalangoang | 30 ° lihora | 16 | 23 | 36 | 50 | 70 | 74 | 105 | 122 | 135 | 164 | 204 | 240 | 300 | 359 |

| Fana ka mohlala | 40 ° lihora | 12 | 19 | 25 | 33 | 60 | 49 | 90 | 106 | 116 | 142 | 175 | 195 | 240 | 310 |

| m³/h | 50 ° lihora | 9 | 15 | 19 | 23 | 41 | 35 | 61 | 75 | 78 | 100 | 120 | 137 | 165 | 210 |

| Bophahamo ba setšoantšo | Head wheel center high H1 | 350-1000 | 1100-2000 | 1300-2000 | 1600-2000 | ||||||||||

| Bohareng ba mabili a mohatla bo phahameng H2 | 350 | 350-500 | 600 | 800 | |||||||||||

| Karolo e bohareng e nang le H3 e phahameng | 450 | 500-700 | 760-800 | 760-850 | 1000-1135 | 1050-1135 | |||||||||

| Karolo e bohareng ea bophara ba ankora ea B1 | 480 | 580 | 870 | 1020 | 1220 | 1440 | |||||||||

Mosebetsi oa Morero

Kopa Khopolo

Khetha mohlala 'me u behe liodara

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana theko ea motheo

Baetsi ba nka bohato ba ho ikopanya le ho tsebisa lo

Tlhahlobo ea limela

Tataiso ea koetliso ea litsebi, leeto la ho boela la kamehla

Saena konteraka

Khetha mohlala 'me u fane ka sepheo sa ho reka

Fumana bonyane tlhahiso ntle le tefo , ka kopo tlatsa lintlha tse latelang ho re bolella ( boitsebiso ba lekunutu , bo sa buletsoeng sechaba )

Haeba u thahasella lihlahisoa tsa rona kapa u hloka ho tseba haholoanyane, ka kopo, tobetsa konopo ea lipuisano ka ho le letona

Fumana khotheishene

Fumana khotheishene +8618937171932

+8618937171932